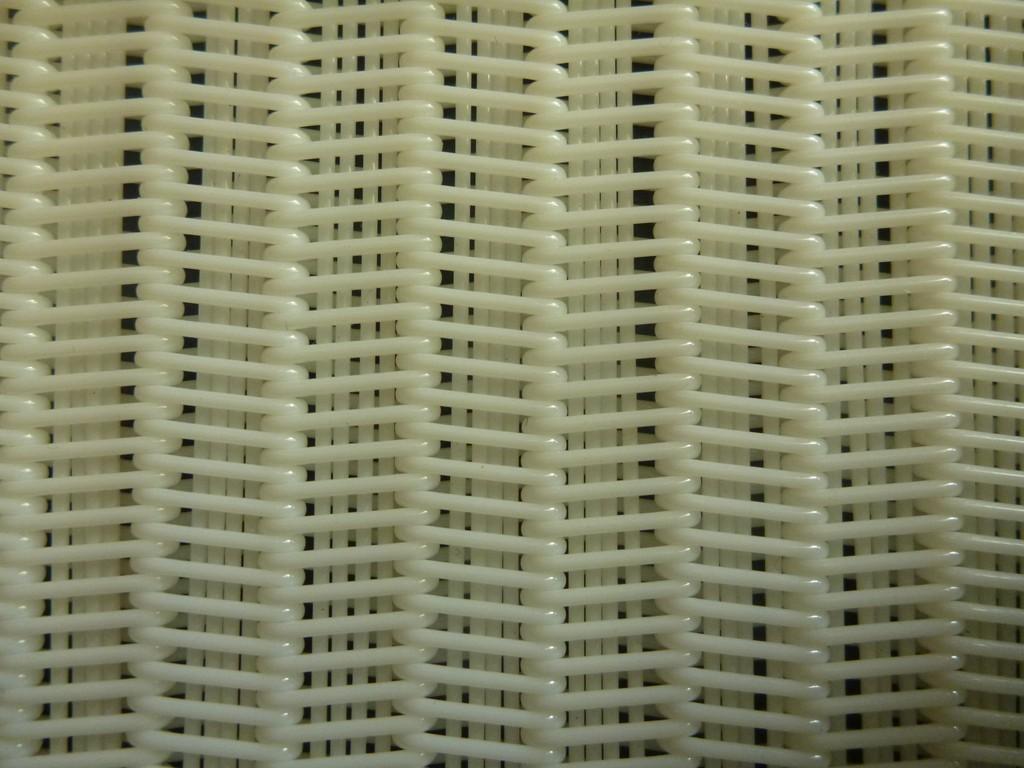

Spiral filter belts

Home / Filter belts /

Spiral filter belts are made of polyester with improved wear resistance.

The main advantage of spiral belts is the strong spiral seam which does not protrude above the level of the fabric. Spiral belts are particularly suitable for use on machines where the stainless steel clipper seam on woven belts has a low service life due to mechanical damage.

Advantages of spiral belts compared to woven belts

- Long service life of the seam.

- High abrasion resistance

- High resistance to deformation and against creating falds in fabric

Application examples

- Dewatering of municipal and industrial sludge on belt presses

- Dewatering of paper sludge and pulp

- Dewatering of sludge in mines

- Sludge thickening on belt thickeners

- Forming fabrics for woodchip production

- Conveyor belts

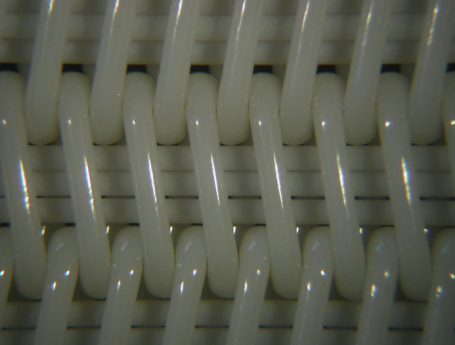

Belt series: HeavySpiral F

Air permeability range: 550 – 900 CFM, Fabric Thickness: 3.1 mm, Spiral yarn diameter: 0.9 mm

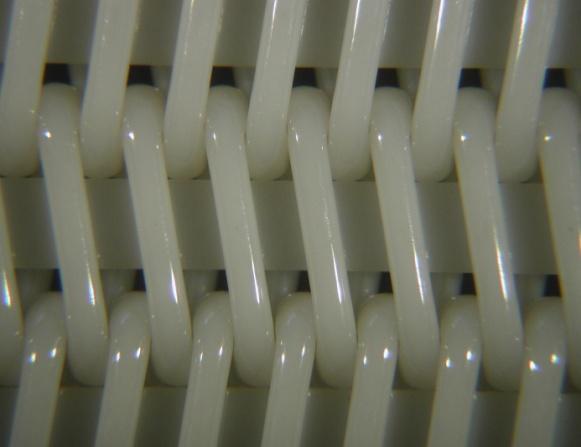

Belt series: SpiralHD-ExtraLife

Air permeability range: 500 – 900 CFM Fabric Thickness: 3.7 mm Spiral yarn diameter: 1.00 mm

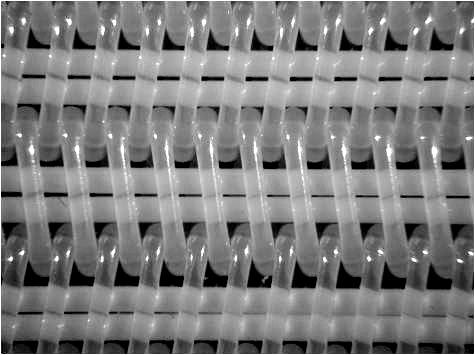

Belt series: Spiral F

Air permeability range: 400 – 900 CFM Fabric thickness: 2.5 mm Spiral yarn diameter: 0.7 mm The most widely used spiral fabric with flat filling yarn.