Filter belts

Home /

Filter belts are used for a wide range of applications in various industries for the separation of aqueous suspensions. Examples of applications include dewatering of industrial and municipal sludge on belt thickeners and belt presses, pressing of fruit juice or vegetable juice on Flottweg presses, filtration of fine suspensions on vacuum horizontal belt filters in the mining industry or in coal fired power plants and other industrial applications.

FiltraPress - Woven filter belts for belt presses

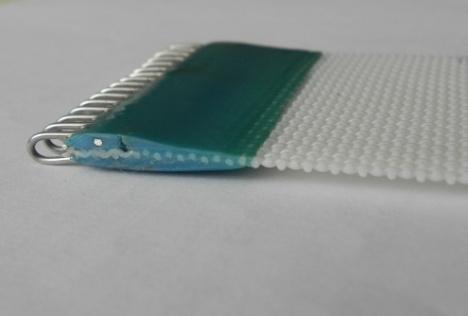

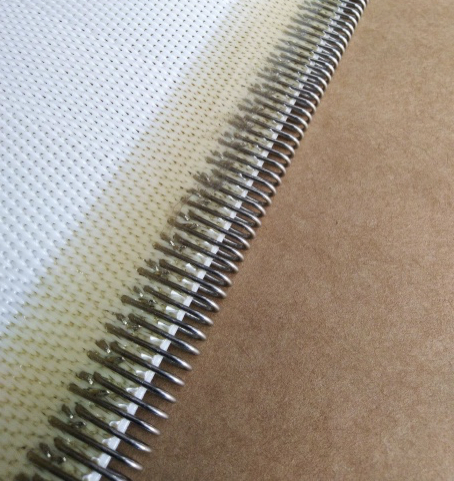

Filer belts FiltraPress for belt presses are characterized by high strength, high abrasion resistance and very good dimensional stability under extreme mechanical stress and high tension. The fabrics are specifically designed to allow the filtrate to flow through the fabric while preventing the filter cake from being pressed inside the fabric. The different types of belts differ in drainage rate, size of holes in the fabric, surface smoothness, wear resistance, etc. The belts are usually joined on the machine to form a continuous belt using a stainless steel clipper seam, or can be supplied endless using a permanent woven seam. The stainless steel clipper seam is protected by polyurethane coating. Belt edges are sealed or can be additionally reinforced with polyurethane coating. Belts FiltraPress are used on belt presses such as Bellmer, Vanex, Klein, Andritz, Huber, Flottweg, etc.

FiltraDrain series - woven filter belts for belt thickeners and drum thickeners

FiltraDrain series includes filter belts with a plain weave and twill weave 2/1. The holes in the fabric are perpendicular to the surface of the fabric and therefore the fabric is very easy to clean and does not clog. FiltraDrain fabrics can be used for sludge thickening or for various filtration applications.

Filter belts for horizontal belt vacuum belt filters

Filter belts for filtration of fine suspensions on horizontal vacuum belt filters are equipped with a conventional stainless steel clipper seam or with a stainless steel cliper seam with a multifilament sealing. Another option is a stainless steel clipper seam with textile overlap or underlap, however this solution is not recommended as a standard, as the flap can generally be a source of operational problems (lower filtration capacity in the flap area, higher belt thickness in the flap area and associated operational problems, etc.). The belts are usually made of polyester or polypropylene. Polyester can be used for neutral or acidic suspensions while polypropylene can be used over the entire pH range. Polyester belts have higher mechanical strength and higher wear resistance than belts made of polypropylene.

Filter belts for vertical belt pressure filter

Filter belts for vertical belt pressure filters are made of robust polyester or polypropylene fabric and are fitted with a strong stainless steel clipper seam. The fabric is either composed entirely of multifilament fibers or a combination of monofilament and multifilament fibers.

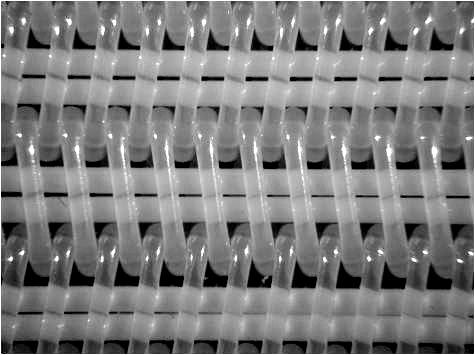

Spiral filter belts

Spiral filter belts are made of polyester with improved wear resistance.

The main advantage of spiral belts is the strong spiral seam which does not protrude above the level of the fabric. Spiral belts are particularly suitable for use on machines where the stainless steel clipper seam on woven belts has a low service life due to mechanical damage.

Edges of filter belts

Edges of all filter belts are heat sealed as a standard. Edges of some types of filter belts are additionally reinforced with polyurethane coating.

Used materials

Our screens are made from only high quality fibres from the world\'s leading manufacturers to ensure a high quality end product.