Dryer fabrics for paper machine

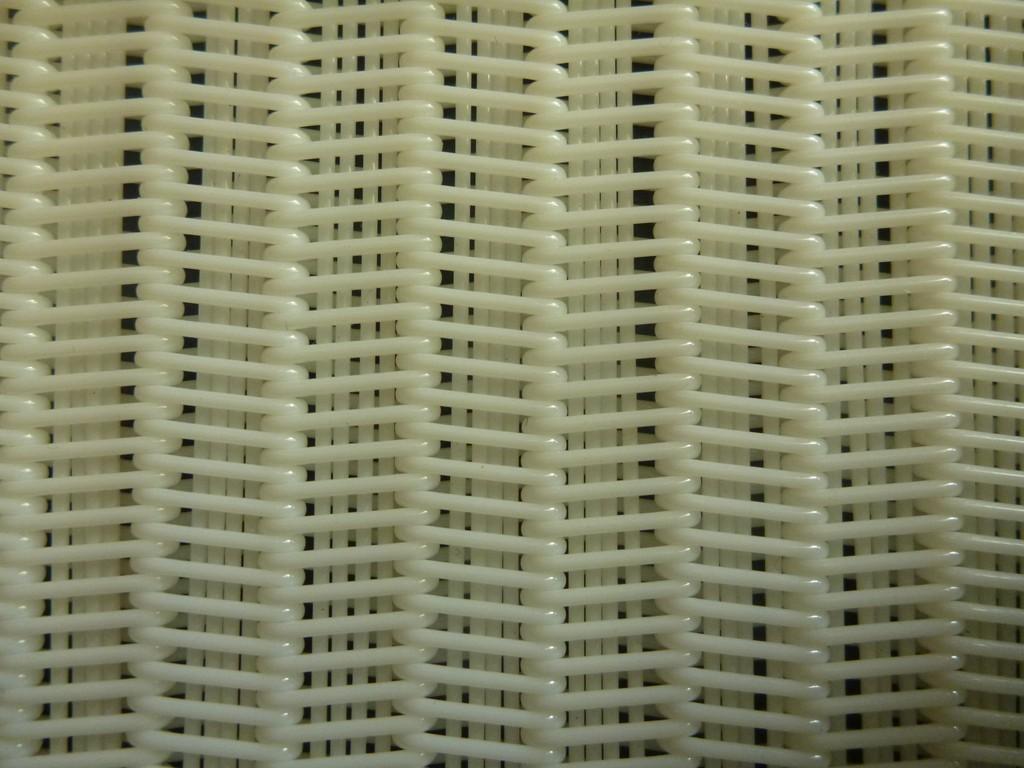

Our dryer fabrics are made of polyester yarns with high hydrolysis resistance from renowned European manufacturers. Another alternative is the use of PPS (polyphenylsulphide), which can withstand temperatures up to 185°C.

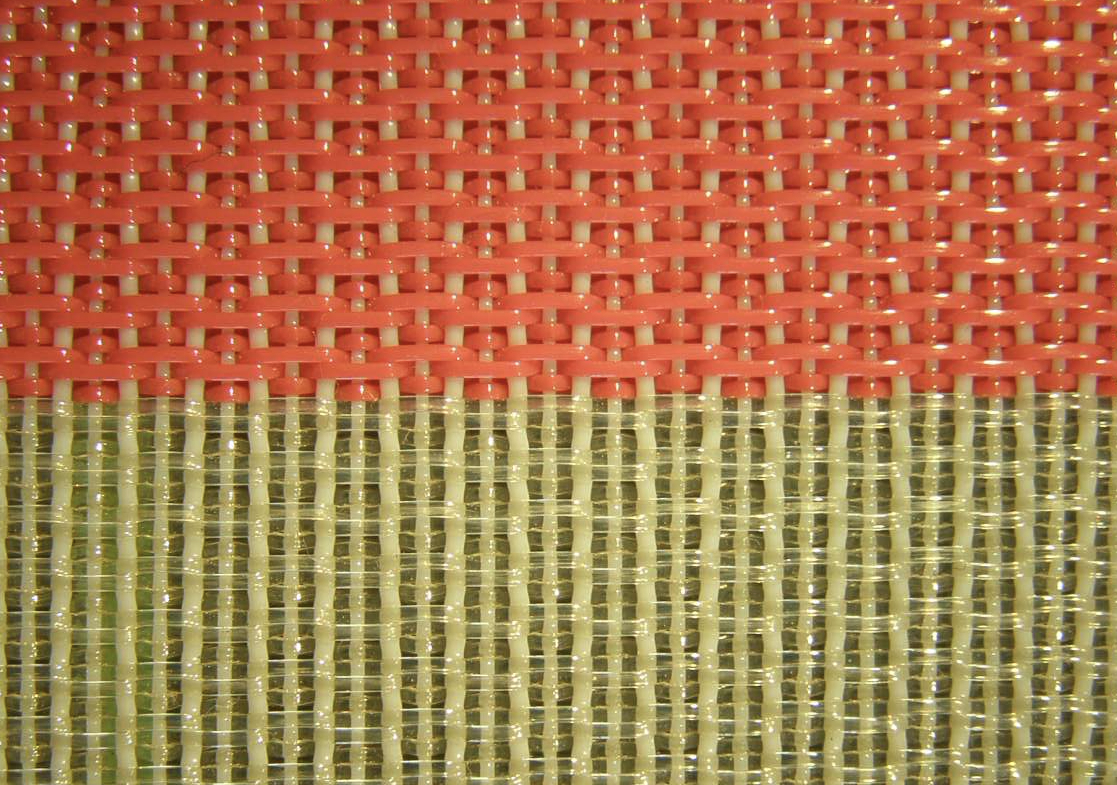

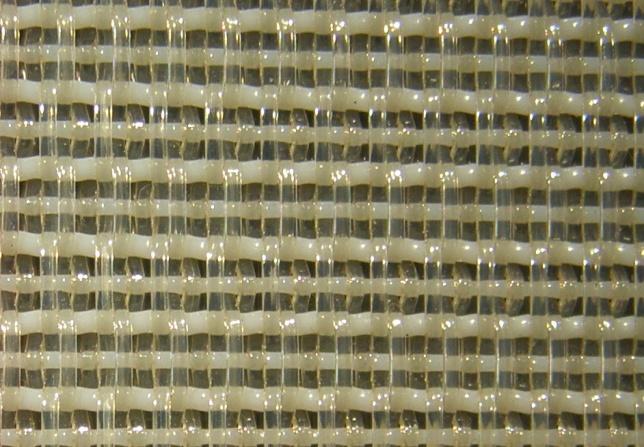

Dryer fabrics can be manufactured within a certain range of air permeability, which is indicated in the technical specification for each individual type. The entire range of dryer fabrics covers an air permeability range from 80 CFM to 1000 CFM.

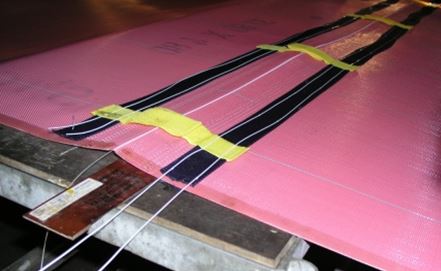

The edges of the dryer fabrics are standardly heat sealed and reinforced with a 4 cm wide strip of polyurethane, which is also resistant to hydrolysis.

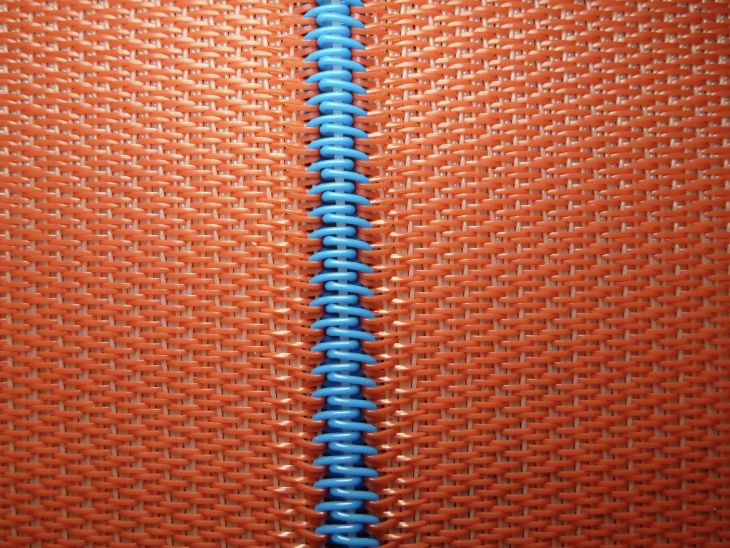

The dryer fabrics are supplied with standard accessories for easy installation and connection (leader cloth, zipper, PET connecting pintle wire with steel inserting wire, silicone sealant).

The supply of the dryer fabrics includes technical support and service in the drying part of the paper machine in accordance with the recommendations of TAPPI (Technical Association of Pulp and Paper Industry).