Edges of filter belts

Home / Filter belts /

Edges of all filter belts are heat sealed as a standard. Edges of some types of filter belts are additionally reinforced with polyurethane coating.

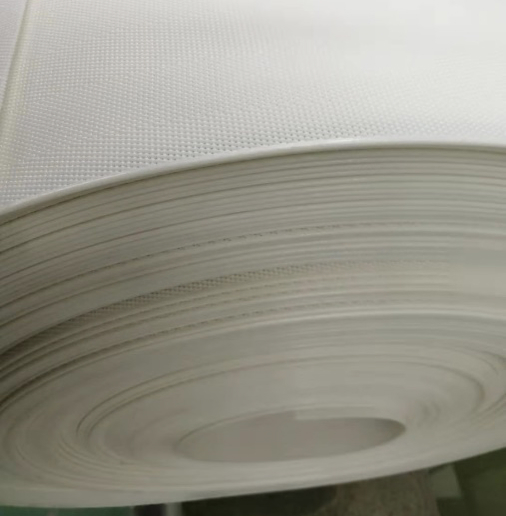

Heat sealed edges

Heat sealed edges are the optimal solution for woven filter belts used on belt presses and gravity thickeners. Further edge reinforcement with polyurethane is not necessary for these filter belts as the fabric itself has a high stiffness and resistance to damage.

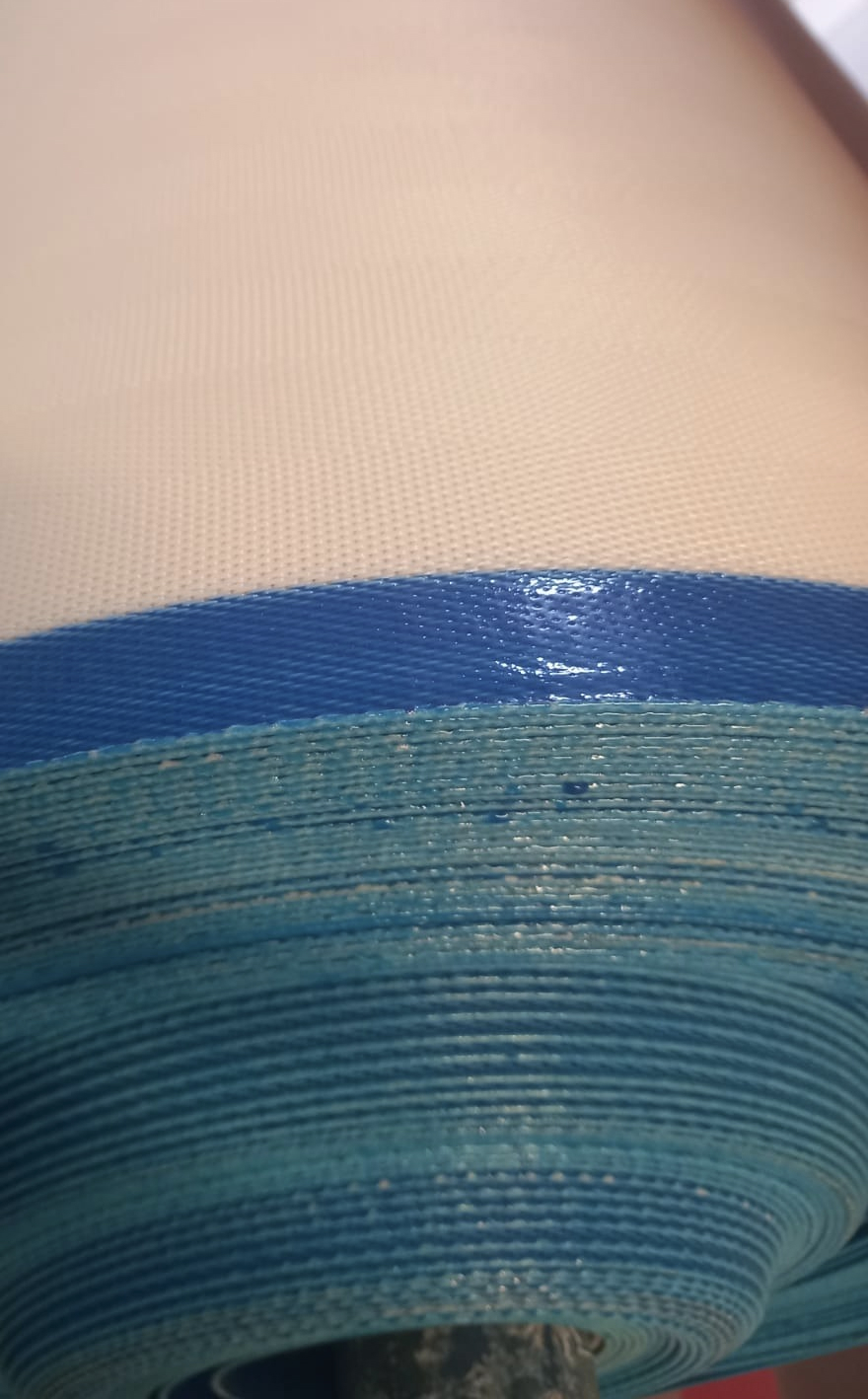

Glued edges

The glued edges are flooded by polyurethane. Heat sealed edges are the optimal solution for woven filter belts used on belt presses and gravity thickeners and additional reinforcement by polyurethane is not needed. However, in the event of edge damage during a belt accident, the glued edges prevent release of longitudinal yarns from the edge of the belt. Glued edges are used as a standard mainly for fine fabrics where there is a need to increase the stiffness of belt edges, or for fabrics with low warp densities where glued edges increase edge mechanical resistance. Glued edges are always used for spiral fabrics which are sensitive to edge damage.