Municipal sludge dewatering

For municipal sludge with low solids content it may be necessary to thicken the sludge on a belt thickener or drum thickener before dewatering on a belt press. Some types of belt presses have a sufficiently long gravity dewatering zone and therefore do not need to thicken the sludge before the belt press.

Production of apple juice

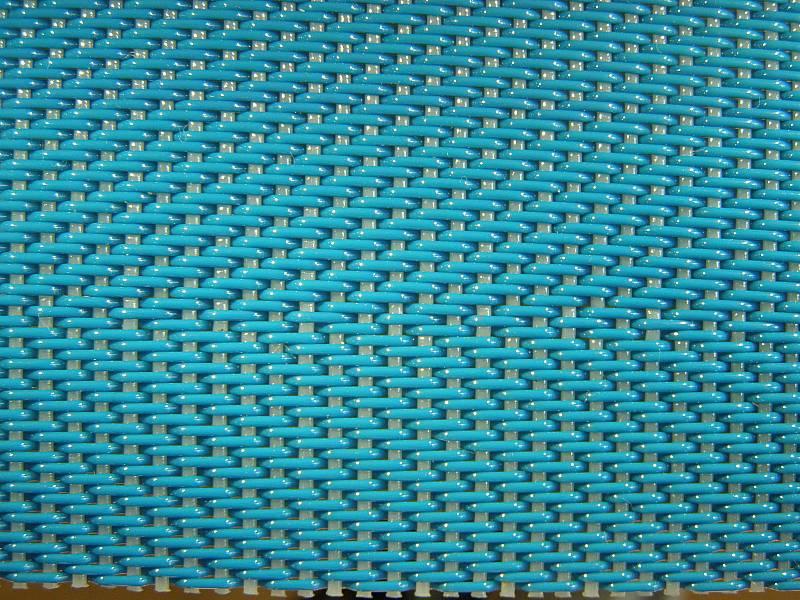

Filter belt FiltraPress SW-Apple was specifically designed for production of apple juice, fruit juice and vegetable juice. This belt has best mechanical and filtration properties and can withstand the extreme tension, which is typical for this application, for example on Flottweg belt presses.

Mining industry

Mining sludges are generally characterised by high abrasiveness and low organic content. The filter cake is usually porous and therefore, in addition to a belt press, a horizontal vacuum belt filter can also be used for continuous dewatering.

Gypsum dewatering in thermal power plants

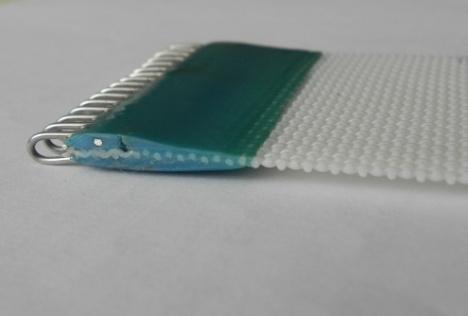

Filter belts for filtration of fine gypsum slurries on horizontal vacuum belt filters are equipped with either a conventional stainless steel clipper seam or a stainless steel clipper seam with a multifilament sealing. Another option is a stainless steel clipper seam with textile overlap, however this solution is not recommended as a standard, as the overlap can generally be a source of operational problems (lower filtration capacity in the ovelap area, higher belt thickness in the overlap area and associated operational problems, etc.). The belts are usually made of polyester, which has the best mechanical properties.

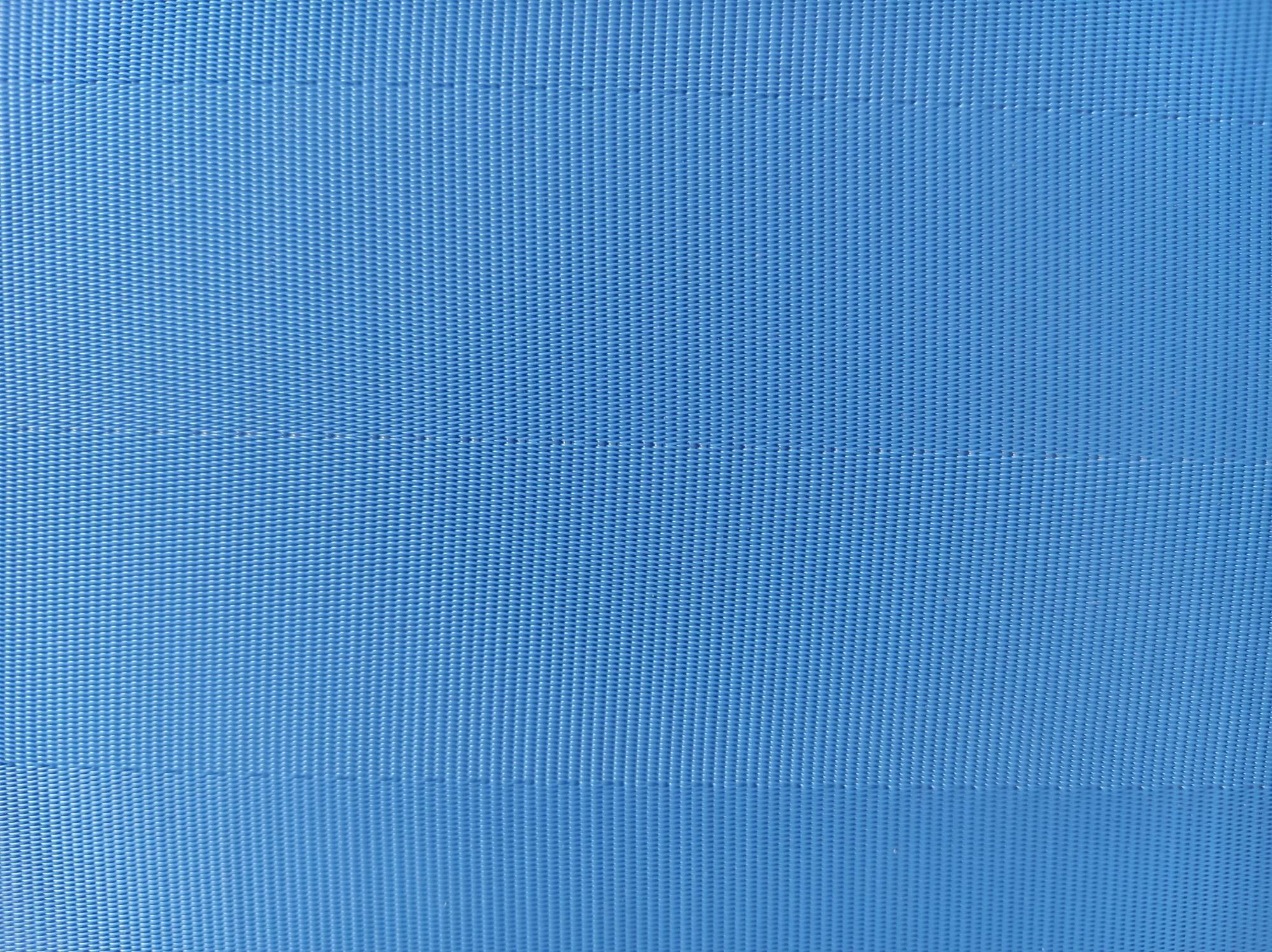

Drying of biomass in industrial dryers

Drying belts for biomass drying are characterised by high air permeability for efficient drying, high surface smoothness for easy separation of the dried material from the fabric and good mechanical properties. The drying belt is joined by a strong stainless steel clipper seam, which is the ideal solution for this application. Some applications require the use of anti-static fabrics to eliminate the risk of static discharge. For operating temperatures above 100°C, a belt material that is resistant to hydrolysis is required.